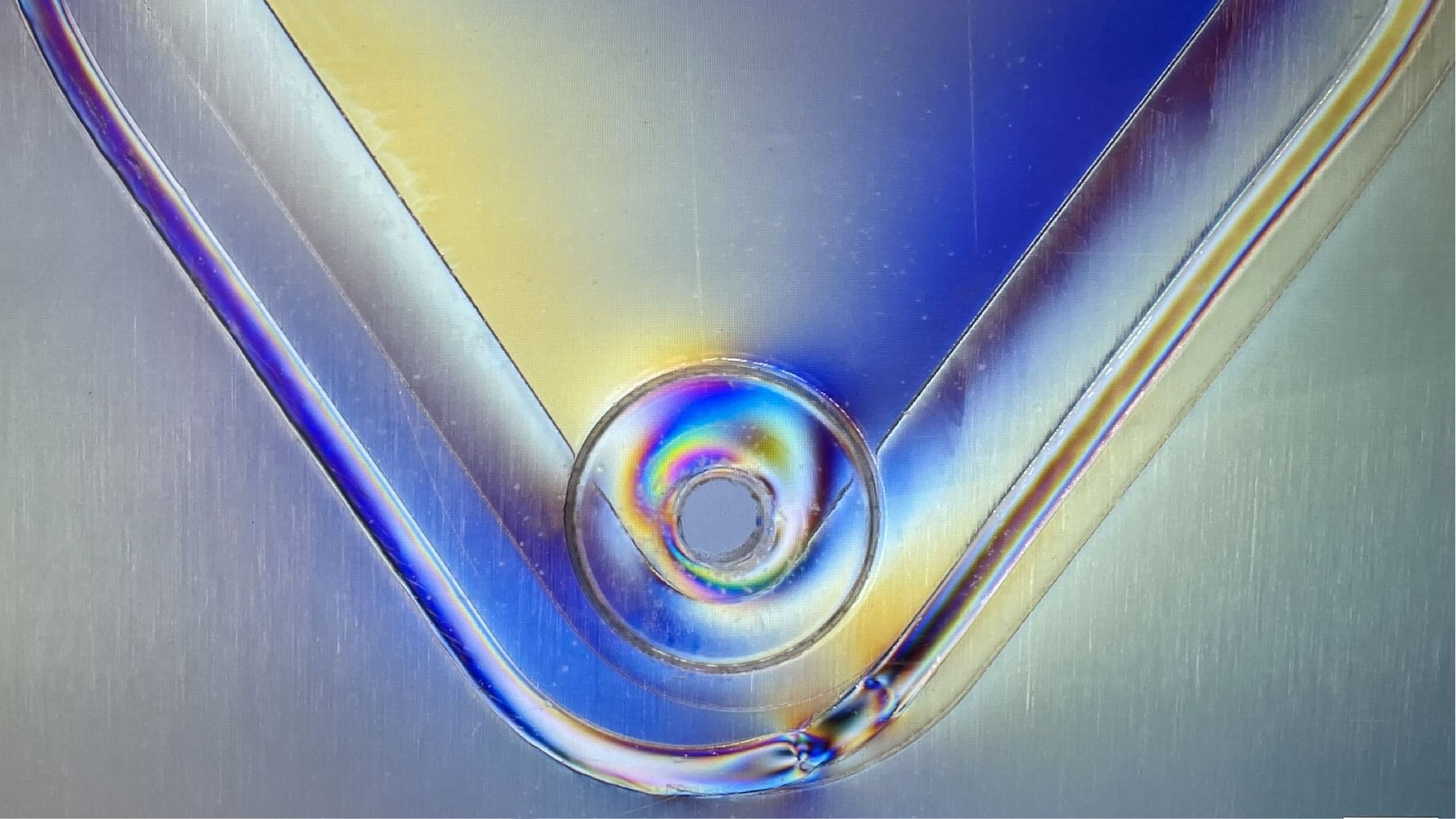

Laser pioneers, Optical Engines Inc. (OEI has developed a groundbreaking 2-µm (micron) laser system specifically engineered for clear plastic welding applications. This state-of-the-art laser system offers exceptional performance and versatility, making it the ultimate solution for a wide range of industries.

Here is a high-level view of the advantages of OEI’s advanced technology.

- OEI 2-µm laser is the only 2-µm system that has a “Top Hat” profile achieved through proprietary beam shaping technology – this avoids burning and other issues that are inherent with gaussian beam shapes

- Air cooled up to 250 Watts – no messy and unreliable chillers

- Much higher efficiency than competitors (>50%)

- OEI’s laser seamlessly integrates to all galvo-scanner types and sizes.

Now let’s dig into the details.

Unprecedented Power and Efficiency

Offering a remarkable 250W of output power, our 2-µm laser sets a new industry standard, ensuring robust and reliable clear plastic welding. What truly differentiates our laser is its exceptional efficiency, which is three times greater than competing lasers. This efficiency not only maximizes performance, it also minimizes operating costs, thanks to an air-cooling mechanism that eliminates the need for complex water-cooling systems.

Ease of Use and Setup

Our 2-µm laser system was designed for user-friendliness. OEI’s hassle-free setup and intuitive system interface enable both experienced technicians and laser welding novices to get started quickly and efficiently.

Versatile Fiber Output and Collimation Optics

The laser system features a 200 µm fiber output and ½” or 1” collimation optics, providing precision and flexibility in welding applications. This versatility offers fine-tuned control, ensuring optimal results for various materials and scenarios.

Enhanced Safety Features

Knowing that safety is a top priority in laser technology, our laser system adheres to Performance Level E safety standards per ISO 13849-1, providing peace of mind to operators and ensuring a secure working environment.

Advanced Control Software and API Suite

Optical Engines’ 2-µm laser includes the Optical Engines Power Drive™ software control, offering a comprehensive suite of tools to manage and monitor the laser system. Additionally, we offer a full API suite for integration into larger automation systems, providing seamless control and optimization.

Unrivaled Precision with Powerlock Output Control

Achieving precise welds is paramount in clear plastic welding applications. Our Powerlock output control guarantees an impressive 1% accuracy, delivering consistently exceptional results in every weld.

Optional Pyrometer and Vision Control

For enhanced control and quality assurance, our laser system can be equipped with optional pyrometer and vision control modules. These add-ons enable real-time temperature monitoring and visual inspection of the welding process, ensuring the highest quality welds.

Unmatched Capabilities

Optical Engines’ 2-µm laser opens a world of possibilities in plastic welding:

No Laser Absorbing Additives Required

Our laser can weld polymers without the need for any laser-absorbing additives. This preserves the natural or approved state of the material, eliminating the need for costly and time-consuming modifications.

Multi-Layer Welding

The laser is capable of welding two or more layers of material, making it ideal for applications where complex films or multi-layer structures are involved. This capability extends up to 15 layers or until the thickness exceeds the processing power of the laser.

Welding Soft-to-Hard and Soft-to-Soft Materials

Our laser system can weld a variety of materials, including challenging combinations like TPE/TPU to polypropylene and flexible PVC to rigid PVC. Such versatility supports applications across industries.

Deeper Weld Penetration

The 2-µm wavelength effectively volumetrically heats the polymers, resulting in deeper penetration during the bonding process. This leads to stronger, more reliable welds.

Welding of Clear-to-White and White-to-White Polymers

Our laser can weld clear-to-white, offering flexibility in material choice without compromising performance.

Compatibility with 1-µm Materials

While optimized for 2-µm welding, our laser can still be used to weld materials that are traditionally welded with 1-µm lasers, expanding its range of applications.

Annealing Potential

Since the 2-µm wavelength is volumetrically absorbed by the polymer, it allows for a certain level of “annealing,” which can enhance material properties.

Wide Range of Applications

Optical Engines’ 2-µm laser is a versatile tool with applications across various industries:

- Medical Devices: Precision welding of clear medical components, ensuring integrity and safety.

- Electronics: Bonding transparent components in electronic devices, maintaining optical clarity.

- Packaging: Welding single- or multi-layer films for secure and hygienic packaging.

- Consumer Goods: Joining clear plastic components in consumer products with precision and strength.

Conclusion

Optical Engines’ 2-µm laser system represents a significant leap forward in clear plastic welding technology. With its unmatched power, efficiency, and versatility, it is poised to revolutionize welding processes across multiple industries. Whether you require precision in medical devices, durability in automotive components, or clarity in consumer goods, our laser system is the ultimate solution.

Investing in Optical Engines’ 2-µm laser means investing in the future of your clear plastic welding applications. With its advanced features, extensive capabilities, and commitment to safety, it is the optimal choice for those seeking innovation, efficiency, and excellent results.

For inquiries, demonstrations, or further information, please contact us at [email protected]

**Optical Engines – Innovating Precision in Laser Technology.**

—

Disclaimer: This article is for informational purposes only and is subject to change without notice. Actual product features may vary. Please contact Optical Engines for the latest information and specifications.