CPTEC Overview

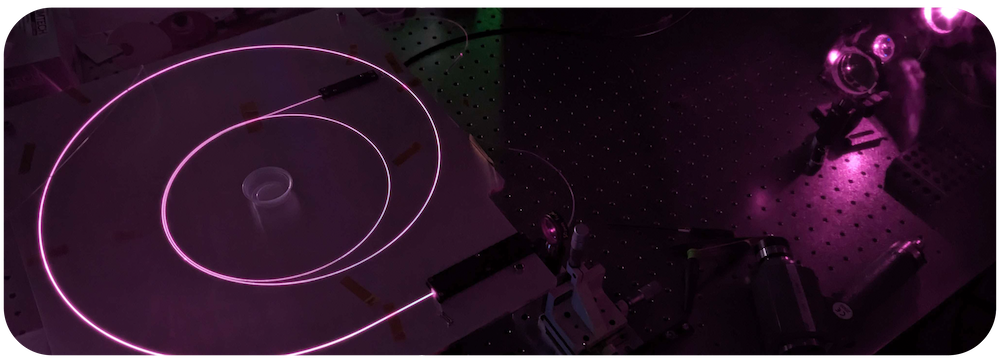

Finding other solutions falling short on several levels, Optical Engines Inc. Developed a proprietary, cutting-edge laser technology called Counter Pumped Tapered End Cap, or CPTEC. CPTEC is a cutting-edge laser technology that integrates the advantages of both fiber and bulk lasers into a compact, rugged, and cost-effective unit. By combining these benefits, CPTEC achieves superior performance in a range of applications, particularly in environments requiring precision, stability, and high power. CPTEC’s design enhances efficiency, reduces costs, and minimizes maintenance requirements, making it an ideal choice for industries that demand reliable, high-performance laser systems.

We make the world’s highest-power all-fiber pulsed fiber lasers, setting a new benchmark in laser technology.

Why Choose CPTEC?

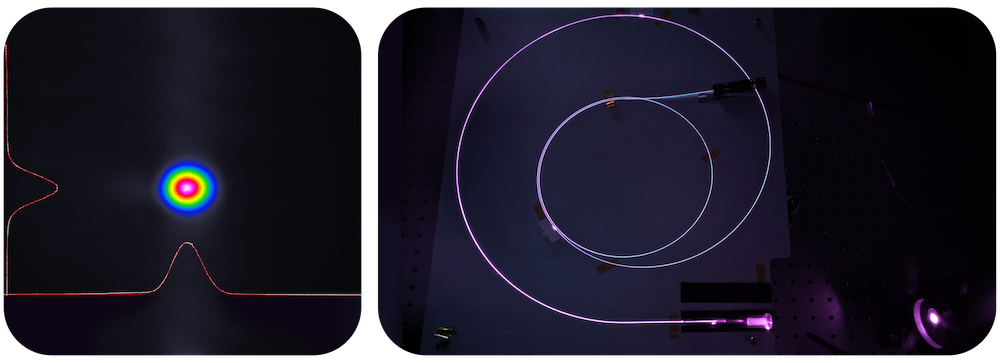

Modal Stability

One of CPTEC’s most significant advantages is its modal stability, a feature that ensures no mode changes occur due to physical movements or thermal expansion, which is otherwise a common issue in traditional lasers. As a result, CPTEC maintains consistent, high beam quality, even when operating at high power, or when subject to vibration or movement, making it especially useful in applications where precision and stability are critical.

Counter-Pumped Design

The counter-pumped architecture of CPTEC enables the system to operate at higher power levels before the onset of non-linear effects, such as stimulated Raman scattering (SRS) or stimulated Brillouin scattering (SBS). This results in higher energy pulses than those typically achieved by fiber lasers and higher average power output compared to bulk lasers, making CPTEC a versatile solution for many industrial and research applications.

Monolithic Structure

CPTEC’s monolithic design, featuring fused fiber components, eliminates the need for realignment. This not only simplifies the system’s operation but also removes potential points of contamination, contributing to minimal maintenance and increased robustness. The absence of exposed optical components ensures that CPTEC operates reliably in challenging environments with reduced susceptibility to external factors like dust or moisture.

Thermal Stability

Thermal stability is another key feature of CPTEC. It reaches full operational capacity in under one minute, reducing downtime and improving productivity. Furthermore, the system is designed to avoid thermal lensing effects, which can distort the beam quality in other laser systems. CPTEC’s fast thermal turn-on time and stable performance make it highly suitable for time-sensitive and high-precision applications.

Gain Medium-Agnostic

CPTEC’s design accommodates a wide range of traditional and exotic gain materials, making it flexible enough to handle specialized fibers such as photonic crystal fibers (PCF), chirally coupled core (CCC) fibers, ultra-large mode-area (ULMA) fibers, and tapered gain fibers (TGF). This adaptability makes CPTEC a powerful tool for industries that require specialized fiber technologies or novel gain media.

Cost and Size Efficiency

Compared to free space-coupled systems, CPTEC offers a significant cost reduction—approximately 30%—while also being compact and rugged. The monolithic design further reduces the system’s size, complexity, and maintenance requirements, providing a cost-effective solution without compromising performance.

CPTEC Features and Specifications

- Monolithic Pulsed Laser: CPTEC is an active fiber-agnostic laser with low thermal turn-on time and excellent beam quality, making it ideal for many applications.

- Beam Quality: M² value of ≤1.2, indicating a high-quality beam with minimal divergence.

- Space-Qualified: CPTEC can withstand extreme vibration and thermal cycling, making it suitable for aerospace and defense applications.

- Wavelengths: CPTEC operates at 1µm, 1.5µm, and 2µm, offering versatility across different industries.

- Pulse Energy: Up to 1mJ per pulse, making it appropriate for applications requiring fine control of pulse energy.

- High Average Power: Capable of exceeding 400W, making CPTEC suitable for high-demand industrial processes.

- Pulse Lengths: From femtoseconds (fs) to nanoseconds (ns), with continuous wave (CW) operation also available, CPTEC can cater to both ultrafast and traditional laser applications.

- Repetition Rate: Greater than 10MHz, enabling CPTEC to meet the requirements of high-speed, high-precision operations.

The development of CPTEC was driven by the need for a laser system that could handle a wide variety of fiber types, including cutting-edge technologies such as photonic crystal fibers (PCF), chirally coupled core (CCC) fibers, ultra-large mode-area (ULMA) fibers, and tapered gain fibers (TGF). These fibers have historically been challenging to integrate into laser systems, but CPTEC’s gain medium-agnostic design makes it an ideal platform for handling these advanced materials.

Fiber Technologies Supported by CPTEC

- Photonic Crystal Fiber (PCF): Popularized by companies like NKT Photonics, PCF fibers offer unique light propagation properties that CPTEC can fully utilize.

- Chirally Coupled Core (CCC) Fiber: Developed by institutions like the University of Michigan and nLight, CCC fibers are known for their efficiency, which CPTEC enhances with its stable and high-power operation.

- Ultra Large Mode-Area (ULMA) Fiber: Supported by companies such as Coherent and Exail, ULMA fibers benefit from CPTEC’s ability to manage high power without mode instability.

- Tapered Gain Fibers (TGF): CPTEC’s compatibility with tapered gain fibers, as used by INO and Coractive, allows for efficient power scaling while maintaining beam quality.

- Rod Fibers: Used by NKT Photonics, rod fibers enable CPTEC to deliver high average power with excellent beam quality.

Case Study: CPTEC in Semiconductor Manufacturing

A semiconductor manufacturing client required an ultrafast laser system that could be easily integrated into their existing infrastructure. By replacing free-space coupling components with CPTEC’s monolithic design, the client achieved several key benefits:

- 30% Reduction in Bill of Materials (BOM) Cost: The switch to CPTEC resulted in significant cost savings.

- Reduced System Size: CPTEC’s compact nature allowed for more efficient use of space within the client’s facility.

- Increased Robustness: The monolithic design eliminated the need for alignment and reduced future maintenance, resulting in greater system reliability.

- Faster Development Time: The simplicity and modularity of CPTEC reduced project development time, enabling faster iteration and product launches.

- Improved Modal Stability: CPTEC eliminated modal instability, ensuring consistent, high-quality output even under varying conditions.

- Faster Build Time and Lower Labor Costs: The client experienced reductions in build time and labor due to CPTEC’s user-friendly design.

- Reduced Thermal Turn-On Time: CPTEC’s thermal stability allowed the system to be operational in under one minute, significantly improving workflow efficiency.

Proven Results with CPTEC

CPTEC delivers measurable improvements for businesses. Its integration has led to a 30-40% reduction in machine size, making it easier to fit into tight workspaces and transport. Additionally, it provides a 30-40% cost reduction, helping companies save money while maintaining high performance.

Conclusion

CPTEC is an innovative laser technology that delivers superior performance, cost-effectiveness, and reliability. Its combination of fiber and bulk laser advantages, along with features like modal stability, thermal stability, and gain medium flexibility, makes it a versatile solution for a range of applications. Whether used in semiconductor manufacturing, aerospace, defense, or research, CPTEC provides the power, precision, and stability needed for modern laser systems.

Interested to learn what CPTEC can do for your business or application? Schedule a consultation with an Optical Engines engineer.